Surface Treatment

Fine Ceramics and Basalt

Material

Fine ceramics

Alumina

A typical fine ceramic material is alumina (AL203).It has three features: it is resistant to acids and alkalis; it has high antifriction properties and heat tolerance; and it has a good balance of mechanical strength.

Alumina is relatively inexpensive and has a long track record in industrial fields.Our company prepares highly pure alumina.

Silicon nitride

Silicon nitride is a high-grade material that has even higher strength and antifriction properties than alumina, and has great toughness and thermal shock resistance, even in high temperature environments.

Basalt

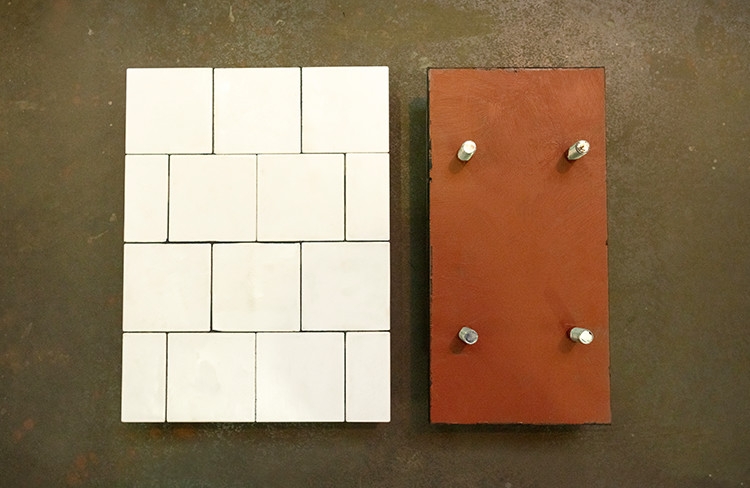

Bonding methods

Bonding methods/characteristics

| Bonding with glue | Bonding by using adhesives such as epoxy resin or silicon-type adhesives.This is an inexpensive and generic bonding method. |

|---|---|

| Rubber vulcanization bonding | Bonding rubber and ceramics by vulcanization.The action of rubber can alleviate impacts on ceramics.The action of rubber can alleviate impacts on ceramics. |

| Bonding by stud welding | Our company’s characteristic bonding method.Mechanical joints by bonding with stud welding display strong adhesion and the thermal effect on the base material is small.This method can be used in high temperature environments as well. |

| Bonding by welded fastening | This method bonds metal to a metal base material by plug welding by utilizing ceramics with hole and metallic parts.This method can be used in high temperature environments as well. |

| Bonding by mortar | The connection by mortar method involves pouring various kinds of mortar between ceramics or basalt and the base material of fittings. |

Construction technique

General industry

Rubber and ceramics liners

We bond ceramics and base materials by vulcanization.Strong impacts on ceramics can be alleviated by coating them with rubber.This is utilized in chutes for masses or powder, hoppers, etc.

Ceramic piping

This improves antifriction characteristics inside pipes by bonding ceramics sleeves with mortar and bonding ceramics chips by gluing.This technology is utilized in conveyance piping for powder or slurry.

| Surface Treatment Department |

|

Ceramics and Basalt Factory Tokyo Business Office |