Electronics

Electronic Device Components

Don’t let it end as just an idea. Pioneering technology that changes the world.

We achieve client satisfaction from the design of pressed products to surface treatments with the consistent quality of our manufacturing technologies.

History of Factory

History of Development

Workpieces pressed at Yoshikawa High Precision Center, Kimitsu Plant are adopted in difficult electronic components such as crystal devices (for which we have a high share in the world), SAW filters, lids for sensor devices, actuators for mobile cameras, and USB type-C (the next-generation standard connector).

In our plants we have prepared a complete production environment based on our long and abundant experience and achievements. It includes a consistent production system (from pressed products to plating products) and tape packaging in a clean room (which each of our plants is equipped with) in order to provide services meeting client needs.

Main developed products

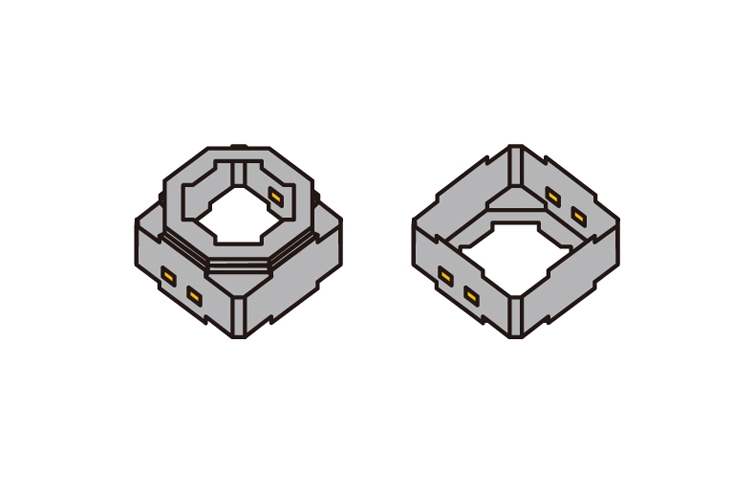

Stepped lids, Flat lids

Crystal devices used for mobile phones and household electronic appliances, SAW filters, and metal covers for sealing the ceramic packages of sensors

Yokes for camera modules,CASE

The component that houses the lens unit in the front-facing camera inside of smartphones. The difficulty level of its processing is very high.

Acute angle drawn caps, flangeless capsCAP

Caps are molded to move the hollow part of a ceramic package to the cover side. Our products result in a large inner volume by giving it an acute angle.

Plug cases for USB type-C

We use progressive die and drawing processing to press plug cases for USB type-C, the next-generation standard connector.

Other products

- Vibration motor cases

- Caps for laser diodes (LD)

- Lead frames for semiconductors

- Caulking

- Drawn caps for LiLID

- Drawn caps for MEMS

- Connectors

- Heat sinks

- Springs for camera modules

- Forming carrier tape

- Metal caps with glass

- AuSn plated boards