Electronics

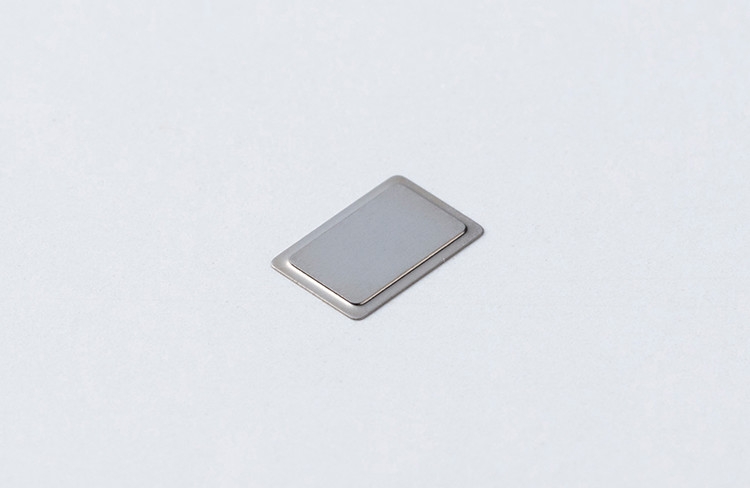

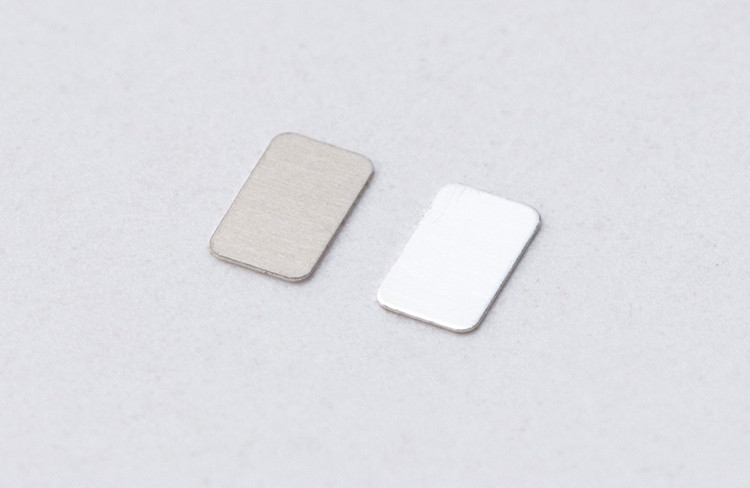

Stepped Lids and Flat Lids

We provide lids, metal covers for sealing the ceramic packages of sensors, SAW filters, and crystal devices for mobile phones and household appliances.

Characteristics of our lids

- Succeeded in the press manufacturing of stepped lids, a world-first in 1989.

- The world’s biggest market share (according to our company survey in 2019).

- Including our domestic market, we have a track record of serving 85% of global customers.

- In-house consistent manufacturing system that covers everything from pressing to plating to testing.

- We can package products using bags, tape, or trays.

- We have a clean room.

Specifications

- Seam type, Ni plated(Electrolytic/Electro-less)

- Solder sealing type, AuSn plating(Three-layer structure of Au-Sn-Au)

- Sliver brazing seam type, AgCu plating(Three-layer structure of Ni-Cu-Ag)

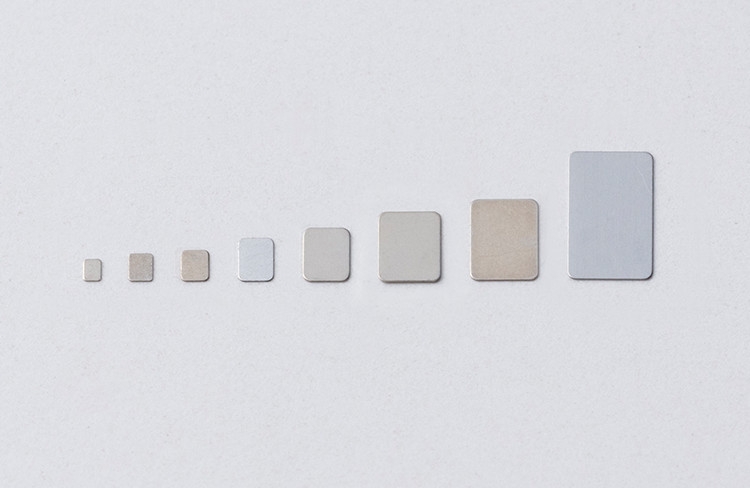

Dimensions

- We have a track record of manufacturing lids for package sizes from 0.8*0.6 mm to large sizes.

Materials

- 29Ni/17Co/Fe Alloy (equivalent to ASTM F15)

Board thickness

- We have thickness of 0.05 to 0.10 mm materials (Consult with us about other board thicknesses.)

Added value

- Lids with holes

- Lids for sensors

- Lids with glass

- Lids with window

Other

- We can deliver prototypes quickly. (If we have a similar size, we can deliver in 10 working days from the time we receive the order)